Ladle Cleaning Shop Floor Upgrade

About this Project

Scope & Objective

Rabcon’s objective was to upgrade a floor to increase its load bearing capacity and improve its resistance to the heat from molten metal transport ladles that are placed on the floor as part of a maintenance servicing procedure to the ladles.

The floor replacement had to be conducted with a minimum of vibration and dust as the normal operations were conducted in the building around and adjacent to project site.

Methodology

Rabcon met with the client staff in the area and conducted risk management studies to produce job safety and environmental analysis that ensured safety and environmental control for the project.

Rabcon developed a procedure to reduce dust by saw cutting the existing floor into sections suitable for removal from the building by forklift. The demolished concrete was then removed from site and delivered to an authorised acceptance depot for recycling.

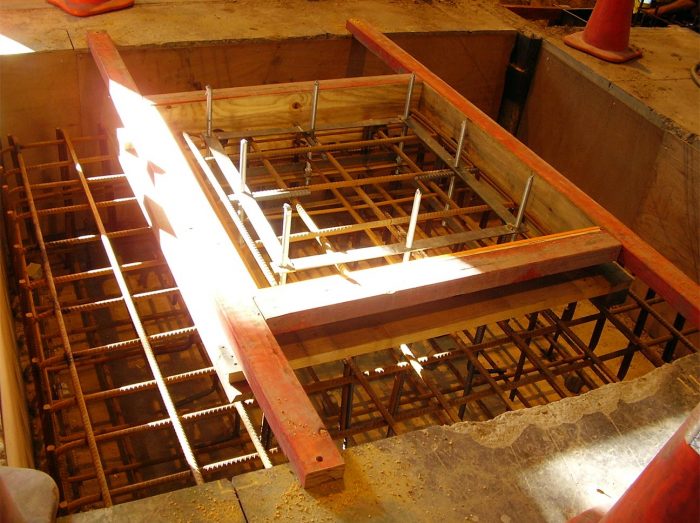

New footings and beams were excavated to facilitate specific increased floor loading.

Approximately twelve schedules of reinforcing steel were supplied and installed by Rabcon.

After acceptance by the client of the Rabcon strict quality control of the reinforcing steel installation, the new floor was poured.

The new floor was poured using 50Mpa high early strength heat resistant concrete.

Result

The client’s operations were able to access the new area within seven days after pouring. The project was completed by Rabcon within budget and program.

Contact Us

4 Abbot Lane Tomago NSW 2322

+61 02 4964 8017

+61 02 4964 8031

+61 417 663 943

After Hours